Heat Treatment Services

Heat Treating (Heat Treatment) is a group of industrial and metal working processes used to alter the physical, and sometimes chemical properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material.

Furnace Structures (Panels)Heber Technical Services has various sizes of furnace panels (structures). Each panel is made to comply with the industry and technical requirements. They meet the highest safety and environmental standards. Our panels are portable and adjustable (in size) so that we could erect any size of temporary furnace at client site according to requirement. We use the most sophisticated methods of erecting the furnace. All our panels are of bolting method, so the furnaces can be erected at site with minimum manpower and time. A maximum of 12mtrs (L) X 4mtrs (W&H) can be erected by bolting system. Above to this sizes are erected and connected by welding of structures one to the other. A maximum of 16mtrs (L) X 6mtrs (W) X 3mtrs (H) and a lower size furnace (4mX3mX1m) for Dish heads & pipe spools can be erected at clients site with our present resources.

Heat Treatment Equipment & Accessories

Heber Technical Services uses Heat Treatment control units (Electrical Resistance) for furnace Heat Treatment, made up of quality components to meet the industry requirements and comply with the top of the safety and environmental standards. The 6 channel 3-phase Distribution/Control Unit has been robustly constructed to provide power to electrical resistance heaters connected to 3-phase mains voltage electrical supply at 380/440V, 50/60 Hz. The unit is suitable for site and shop working. The output from the unit is split into six individual heating circuits for temperature control. Each output circuit has a switching capacity of 63A, 3-phase, which is sufficient capacity for three standard channel heaters rated at 13kW, 240V connected in star. Similarly ceramic heating pad rated at 10.8kW, 240V also can be connected in star. Each of the six circuits may be controlled individually using energy regulators as well can be connected to automatic programmers. Each individual heater can be controlled by 63A MCB in the unit. The unit is made of various renowned brands from U.K and EU.

Heber Technical Services uses the portable and solid elements which are suitable for the furnace heat treatment of pressure vessel welds and sections or other large fabrications. The heater element is manufactured from solid drawn 9swg Kanthal or nickel-chromium coiled wire. The heaters are manufactured with the traditional ceramic sleeves. The heaters are suitable for heat treatment temperatures up to 1050 Deg.C. The heater voltage is 240V.Heat transfer to the component is effected by combined radiation and convection.

Heber Technical Services has got number of Local Heat Treatment units to cater various requirements of our clients. We generally use the 65kVA heat treatment unit to provide power to electrical resistance heaters at 60 volts, suitable for site and shop working

Heber Technical Services uses various types of Ceramic Pad Heating elements according to the size and shape of the work piece. The ceramic pad is manufactured from high alumina ceramic beads with a nickel-chromium flexible core wire serpentined within the beads. Nickel tails are weld to the core wire. The pads are flexible and suitable for heat treatment temperatures up to 1050 Deg.C

Heber Technical Services has selected the 12 channel analogue Temperature Recorder as ideal for the rigours of site heat treatment. The recorder is potentiometric, self-compensating for ambient temperature and operates over the temperature range 0-12000C.

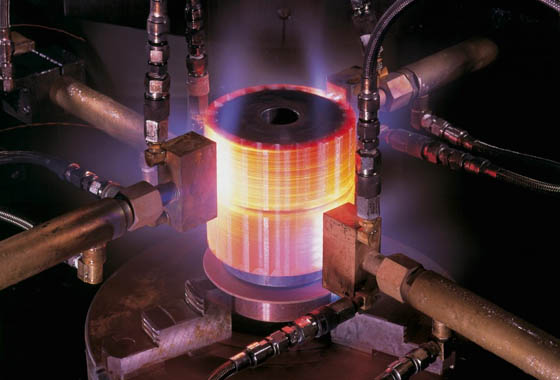

Heber Technical Services uses High Velocity Oil Fired Burners (Rating: 8 Mill BTU/hour each) and Gas Combustion Burners for Heat treatment of vessels and spheres by internal firing and on temporary heat treatment furnaces.